Reduction of CO₂ Emissions

The Tobu Group considers the reduction of environmental impact through means such as the further improvement of environmental advantage as a Materiality that we must solve. In particular, with regard to CO2, as a greenhouse gas with a significant impact on climate change, we will reduce emissions by 30% by FY2030 compared with FY2022, and aim for zero emissions by FY2050. In the Oku-Nikko area, which has been designated as a priority area for decarbonization by the Ministry of the Environment, we will aim to be a pioneer in achieving carbon neutrality by FY2030.

To achieve this goal, we are endeavoring to reduce CO2 emissions through energy-saving initiatives, including the introduction of energy-saving railcars, LED lighting, and high-efficiency air-conditioning systems, as well as actively introducing solar power generation and other forms of renewable energy.

Launch of “NIKKO MaaS” Japan’s first eco-friendly MaaS for tourism, realization of 100% renewable energy in railway transportation, and operation of biofuel buses

Since October 2021, Tobu Railway, Tochigi Prefecture, and four other business providers have rolled out Japan’s first eco-friendly MaaS for tourism, “NIKKO MaaS” in the Nikko area of Tochigi Prefecture, and are promoting the use of public transportation.

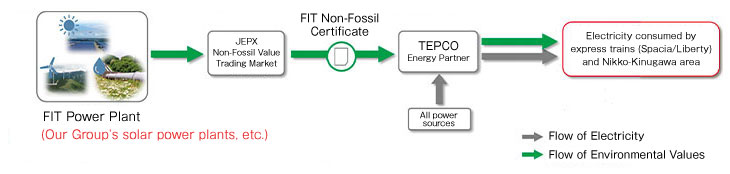

In addition, since April 2022, Tobu Railway has replaced the equivalent amount of electricity used for railroad transportation in the Nikko/Kinugawa area, as well as for express trains running from central Tokyo to the area, with electricity derived from renewable energy sources. In FY2023, we replaced approximately 30.7 million kWh of electricity on an annual basis, resulting in a reduction of approximately 13,000 t-CO2 (equivalent to approximately 4,100 average households).

Furthermore, in the future, biofuel created by refining waste cooking oil generated at Tobu Group facilities in Tochigi Prefecture will be used in buses, etc., in the Nikko area, with the aim of creating a locally produced, locally consumed energy cycle.

By simultaneously promoting the transition to a decarbonized society and the revitalization of the region through the promotion of excursion tourism, we will strengthen the Nikko region’s brand as an “International Eco-Resort Nikko” and aim to become a role model for decarbonization efforts in tourist destinations.

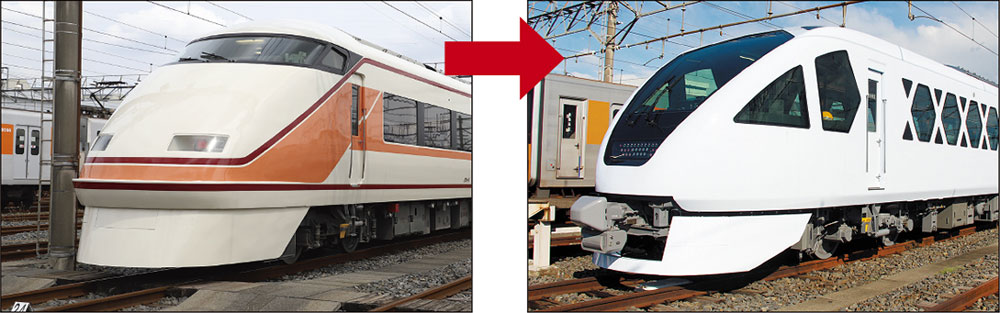

(100 Series)

in the Nikko/Kinugawa area

Biocoke/biodiesel blended diesel oil “B5”

In January 2024, we launched a demonstration test to replace some fuel (coal) for “SL Taiju” with biocoke derived from plant-based materials, with the aim of achieving carbon neutrality in the future. This is the first use of biofuel for a steam locomotive in Japan.

In this experiment, we replaced 40% of the fuel with biocoke in the fire retention work, where coal is constantly burned to maintain the pressure of and protect the steam locomotive boiler. We are verifying the feasibility of this fuel, including its combustion efficiency and impact on the boiler. At the same time, we have also replaced approximately 50% of the fuel (diesel oil) used in DL Taiju (diesel locomotive) with biodiesel fuel blended diesel oil “B5.”

We expect these efforts to reduce annual CO2 emissions at least 150 tons (equivalent to the annual CO2 emissions of approximately 50 households).

Based on the results of this experiment, we will consider full-scale operation, while also continuing experiments to increase the ratio of biofuel use in coordination with initiatives to create a “locally produced, locally consumed energy cycle,” in line with the aim of Tobu Bus Nikko, which will operate biofuel buses in the Nikko area in the future.

Measures against overtourism

(Nikko during the fall foliage season)

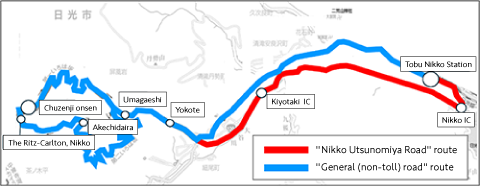

As part of measures against overtourism during the fall foliage season in Nikko, Tobu Bus Nikko operated express buses via the Nikko-Utsunomiya Road, avoiding spots with traffic congestion in downtown Nikko, on the bus route between the Lake Chuzenji area, a major fall foliage spot, and Tobu Nikko Station, for a total of 20 days in October and November 2024. We conducted this initiative to reduce CO2 emissions in support of the efforts of Nikko City in Tochigi Prefecture to promote decarbonization through the active use of public transportation, following its enactment of the "Nikko City Ordinance for Achieving a Zero Carbon City through Community Circulation” in March 2024, in response to congestion in downtown Nikko, which has long been an issue. In addition, the Tobu Group promoted peak shift measures, such as the off-peak operation of the Lake Chuzenji Pleasure Boat and the Akechidaira Ropeway early in the morning, and the operation of night trains that arrive at Tobu Nikko Station early in the morning and special limited express trains. Through collaboration between the public and private sectors on these efforts to create sustainable tourist destinations and take measures against overtourism, we aim to maximize the tourism value of “International Eco-Resort Nikko.”

Railway Business

In the Railway Business, Tobu Railway has been striving to reduce the emission of CO2 through energy-saving vehicles and equipment and efficient operation. By continuing to make systematic reductions, we expect to achieve a reduction of approximately 50% by 2030, exceeding the government’s greenhouse gas reduction target of 46% (compared with FY2013).

Railway vehicles

Introduction and renewal of energy-saving vehicles

Tobu Railway consumes a large amount of electricity in the operation of its trains and is therefore promoting various initiatives to make its rolling stock more energy efficient and its operations more efficient. The new N100 series "Spacia X" express train, which began service in July 2023, has achieved a 40% reduction in energy consumption compared with the previous 100 series "Spacia" by reducing the weight of the car body, improving the performance of the control system, and other measures.

In addition, the train's operating data are analyzed and used to create optimal running patterns and operating diagrams, and environmentally friendly equipment is installed to further promote energy conservation.

Changes in electric power consumption per 1 km/vehicle of travel

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 |

|---|---|---|---|---|

| 1.74 | 1.67 | 1.65 | 1.66 | 1.67 |

Utilization of the “Remote*” onboard data monitoring system

On-board data monitoring equipment has been installed on vehicles since 1997 and is mainly used for maintenance purposes. Since 2016, we have been able to transmit a variety of on-board data from running trains in real time, and instantly acquire, accumulate, and analyze detailed data.

The collected on-board data, such as occupancy rate, cabin temperature, operating speed, power consumption, and equipment status, are analyzed and utilized to optimize train operation diagrams and promote energy-saving operations.

- * Remote: Remote monitoring of train to use effectively

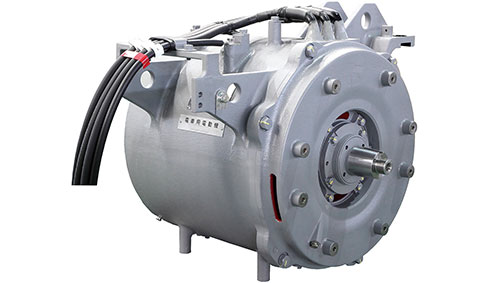

Permanent magnet synchronous motors

A permanent magnet synchronous motor (PMSM) is a device that uses permanent magnets (which generate a magnetic force without electricity) instead of electromagnets (which generate a magnetic force when electricity is applied) for some parts of the conventional main motor.

This reduces the amount of electricity used for the electromagnets, thus improving energy efficiency.

It has been installed on a trial basis since FY2011, and has been introduced on a full-scale basis with the Series 500 and Series 70000 trains.

Permanent magnet synchronous motor (PMSM)

VVVF inverter controller

In the past, DC motors, which are relatively easy to control in terms of speed, were generally used, but recent advances in semiconductor technology have made it possible to control the voltage and frequency freely using a device that converts 1,500 VDC into AC voltage. This converter is called a Variable Voltage Variable Frequency (VVVF) controller. By changing the rotational force of the motor more smoothly than the method of changing the resistance value of the main resistor used in DC motors, more efficient control is possible and significant energy-saving effects are brought about.

Series 500 VVVF Inverter Controller

Regenerative braking system

A regenerative braking system uses the main electric motor as a generator and supplies the generated power to other trains running (accelerating) nearby through pantographs and overhead wires resulting in braking by rotational resistance in power generation as load.

The energy that used to be discarded as heat can now be effectively utilized. Trains equipped with a VVVF controller in recent years can easily incorporate a regenerative braking system.

Lightweight aluminum alloy body

Aluminum alloy is lighter than other metals, so trains can run with less power consumption than ones with conventional steel bodies.

Switch of lighting inside vehicles to LED

We are trying to reduce the amount of electricity consumed by replacing conventional fluorescent lighting with LED lighting inside the vehicles.

Railway facilities

Switch of lighting to LED

We are gradually upgrading the lighting fixtures in our station facilities to energy-efficient LEDs. By replacing fluorescent lighting fixtures with LED ones, we have achieved a long life of 40,000 hours and a reduction in power consumption of more than 70% compared with the old lighting fixtures.

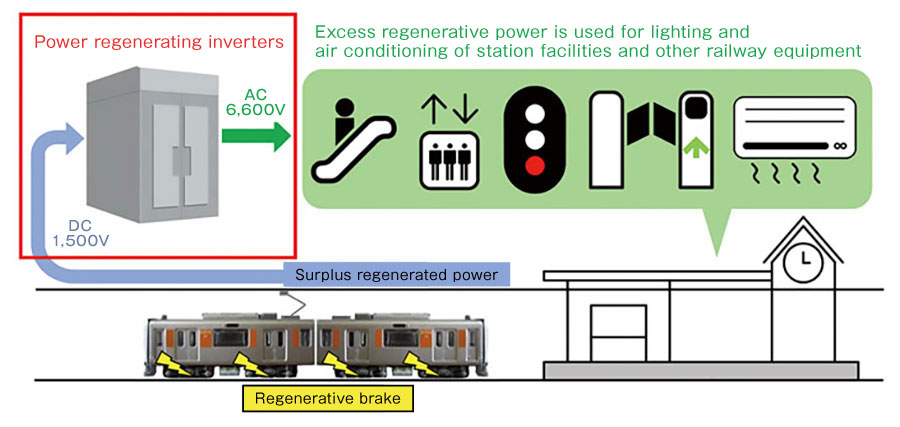

Regenerative power storage and inverter

A regenerative power storage device absorbs and stores the regenerative power generated when braking through the overhead wires, and supplies the stored power to other trains when they accelerate, thereby realizing a stable supply and effective use of power.

This device is installed at two locations: Omiya-Koen Station on the Tobu Urban Park Line and at Kamifukuoka Sectioning Post on the Tojo Line.

Similarly, power regenerative inverters are energy-saving equipment that convert excess regenerative energy (DC power) during train deceleration into AC power, which is then supplied to lighting and air conditioners in the station. In order to make effective use of the regenerative power, we have installed these inverters at the Nishiarai Substation on the Tobu Skytree Line and at the Fujimino Substation on the Tojo Line, and they have both been in operation since June 2024.

Residential Property Sales and Leasing Business

Supply of environmentally friendly housing

In the detached housing “Solaie Shimizu Park Urban Park Town,” we have introduced a method called “passive design,” which uses the power of nature to create a comfortable living space.

Based on this method, we have adopted a functional floor plan that allows wind to flow naturally and an open exterior design.

In addition, houses are delivered with a high thermal insulation performance that meets the Flat 35 criteria.

Townscape of Solaie Shimizu Park

Urban Park Town

Sustainable neighborhood development through five-party collaboration among industry, government, and academia

Kuki City, Tobu Railway, Toyota Home, Aeon Retail and Hiroshi Onoda Class of Waseda University have established the “BRIDGE LIFE Platform,” a next-generation neighborhood development project through industry-government-academia collaboration around the Minami-Kurihashi Station.

In order for these five parties to work closely together and cooperate to promote the project, an “Agreement on Cooperation and Collaboration in Neighborhood Development” was executed.

In detached houses for sale, energy-saving systems such as high-efficiency air conditioners and LED lighting, energy-creating systems including solar power generation, and home energy management systems (HEMS) that control these systems are used, based on homes with high thermal insulation. Homes are designed as a Zero Energy House (ZEH), aiming to reduce annual energy consumption (primary energy equivalent) to net zero or less.

The project received the Good Design Award 2023 from the Japan Institute of Design Promotion.

Given the challenges facing rural and suburban areas, such as population decline and aging, we believe that this project has been highly recognized for actively sharing knowledge among industry, government, and academia, enabling the five parties to realize environmentally friendly and next-generation smart cities while leveraging their respective strengths.

Evening scene from BRIDGE LIFE Platform Minami-Kurihashi

Introduction of high-efficiency water heaters

We have introduced high-efficiency water heaters in condominiums to reduce CO2 emissions and prevent global warming.

Example of facilities installed: Solaie Gran Nagareyama Otakanomori, Solaie Shinkamagaya, Solaie Wakaba Station Villa, Solaie Shimizu Park Urban Park Town

Exterior view of Solaie Shinkamagaya

Solar power generation and storage batteries

Solar panels and storage batteries have been installed in condominiums to supply renewable energy to the common areas in consideration of the environmental impact.

Example of facilities installed: Solaie Gran Nagareyama Otakanomori

Exterior view of Solaie Gran Nagareyama Otakanomori

Introduction of high-efficiency facilities

In the construction and renovation of station buildings, etc., we have gradually introduced high-efficiency equipment for air conditioning and lighting in common areas of facilities to reduce power consumption.

EQUiA Shin Kashiwa

Acquisition of the highest rating of “BELS*”

TOBU icourt (Dokkyo University-Mae), a commercial facility that opened in March 2023, is based on the concept of a place that offers everyone a "comfortable lifestyle" that satisfies the five senses of body and mind. The property generates approximately 10% of its annual electricity consumption through on-site power generation using approximately 980 rooftop solar panels.

This is the second property to receive the 3-star BELS certification, a third-party certification system that indicates the energy-saving performance of buildings, after the “Tobu Zoo Station West Exit Commercial Facility,” which opened in September 2021.

The "Tobu Zoo Station West Exit Commercial Facility" received the highest rating of 5 stars for its in-house power generation using solar panels, which accounts for approximately 1/3 of the facility’s electricity consumption and is environmentally friendly as a green building.

- * BELS: Building-Housing Energy-efficiency Labeling System

Operation of “Top-level Business Site”

TOKYO SKYTREE TOWN, which is operated by both Tobu Railway and Tobu Tower Skytree, was certified as a “Top-level Business Site” under the Tokyo Metropolitan Ordinance on Environmental Preservation in 2017 and 2021, and the operation is ongoing. This accreditation is based on the Tokyo Metropolitan Ordinance on Environmental Preservation, which stipulates the “obligation to reduce total greenhouse gas emissions and the emissions trading system,” and certifies business establishments that have made outstanding efforts in all evaluation items (at the time of accreditation) related to carbon dioxide reduction management systems and building/facility performance stipulated by Tokyo Metropolitan Government.

In March 2022, the “Center Plant” of Tobu Group Nishi Ikebukuro Heat Supply was again accredited as a “Semi-top Level Business Site,” and the “TOKYO SKYTREE District Heat Supply Facility” operated by Tobu Energy Management was again accredited as “Top-level Business Site” in March 2021 and continues to operate.

DBJ Green Building Certification

In February 2012, TOKYO SKYTREE EAST TOWER®, located in TOKYO SKYTREE TOWN®, received the highest rank of DBJ Green Building certification, “Platinum 2012” (a top-class building in Japan with outstanding “environmental and social considerations”).

The building was highly commended as having (1) excellent environmental performance based on the latest technologies, such as rainwater harvesting, solar power generation systems, and the use of geothermal heat for air conditioning, (2) high disaster prevention performance through the installation of an emergency power supply for long-hour operation, in addition to advanced vibration control devices, and (3) in conjunction with the commercial facility “Tokyo Solamachi®,” a design that takes into consideration the history and culture of the Oshiage area, and a community bus stop and other initiatives that contribute to the local community.

Certified as “low-carbon heat” supplier

In February 2024, Tobu Energy Management, Nishi-Ikebukuro Heat Supply, and Kinshicho Heat Supply, three heat supply companies for the Tobu Group, were certified as “low-carbon heat” suppliers under the Tokyo Metropolitan Ordinance on Environmental Preservation.

Under the “obligation to reduce total greenhouse gas emissions and the emissions trading system,” businesses with a low CO2 emission factor (CO2 emissions per unit of electricity or heat supplied) are certified for each fiscal year.

The CO2 emission factor of the TOKYO SKYTREE District Heat Supply Facilities is approximately 40% lower than the standard CO2 emission factor for heat supply facilities designated by the Tokyo Metropolitan Government, due to introduction of high-efficiency heat source equipment and large-capacity water storage tanks, and we have made it one of the top-class facilities in Tokyo.

Solar Power Business

< Tobu Energy Management >

TOBU ENERGY MANAGEMENT is engaged in the solar power business to promote measures to reduce environmental impact and contribute to the creation of a sustainable, vibrant, low-carbon, recycling society.

The estimated annual CO2 reduction from solar power generation is approximately 4,900 tons (equivalent to approximately 1,500 average households).

Forest Conservation and Offset Credit

< Conservation and utilization of company-owned forests >

Forests have a variety of functions, such as land conservation, recharging of water resources, prevention of disasters, and conservation and formation of biodiversity. In particular, the function of absorbing CO2 plays a major role in preventing global warming.

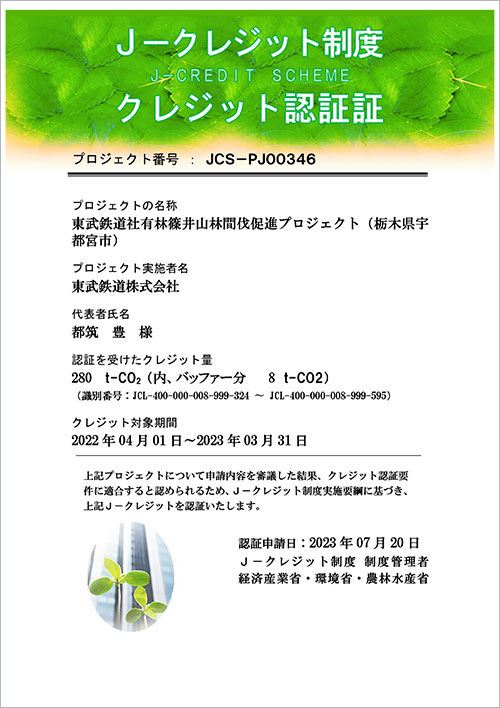

Tobu Railway appropriately maintains and manages company-owned forests in Tochigi, Gunma and other prefectures. The company-owned forests in Utsunomiya, Tochigi Prefecture, have acquired offset credit certification for the amount of CO2 absorbed by thinning in cooperation with the local forestry cooperative. The acquired credits are used for offsets, etc., for the CO2 emissions generated by the activities of the Tobu Group and other companies and organizations.

The Company's forests that are subject to offset credits are properly managed by thinning, trimming and pruning, and the CO2 absorbed through this management has been approved for registration as a forest absorption system project under the domestic credit system administered by the Ministry of Economy, Trade and Industry, for which the offset credit (J-Credit) certification has been obtained.

- J-VER: 797t-CO2

- J-Credit: 272t-CO2

The trading and distribution of J-credits was previously limited to negotiated transactions or tender sales by the government, but in October 2023, trading began on the "Carbon Credit Market" opened on the Tokyo Stock Exchange, and we have registered our certified offset credits with the exchange.

Wood generated from the thinning of company-owned forests is used as a material for station benches, etc., at Asakusa Station and Tobu Nikko Station, and is also widely used for novelty goods to be distributed at events, etc.